EQUIPMENTS

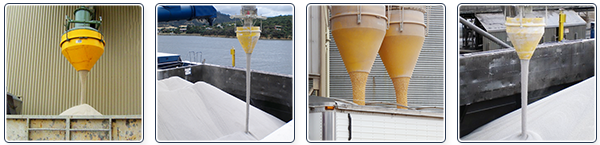

DSH SYSTEM

At the point of loading, the DSH dust suppression system concentrates the discharge of dry goods as a moving solid column through free air into any target repository including, ships, trucks, railcars, stock piles, storages containers or bags.

Materials: fertilisers, grains, stock foods, foodstuffs, minerals, quarry and other bulk materials.

· For more information, please download DSH brochure.

· For a commercial offer to suit your requirements please fill in the form and send it to info@elcris.ro.

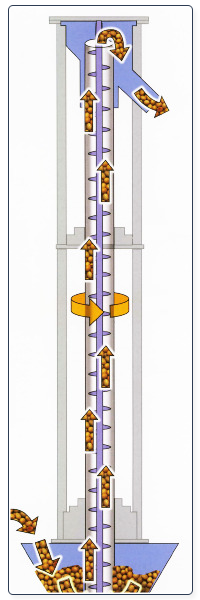

OLDS ELEVATOR

Inovation in bulk material elevation

Design and operating characteristics

· Static screw – only one moving part in contact with the bulk material, a tubular casing with attached in-feed scoops that rotates around the static screw

· Accurate feed rate control from 0 to several hundreds RPM with variable speeds

· Can handle fragile and difficult materials with minim particle damage

· Quieter functioning

· No back-flow

Easier feeding

· Material can enter at any point around the fixed screw

· Fixed screw – smaller feed resistance – less free material

Easier maintenance

· Bearings and other working parts are external to the product minimizing contamination of product and components

Materiale ce pot fi manevrate cu elevatorul OLDS

· Different bulk materials from a wide range of products: Foodstuffs, iron, chemicals, cement, minerals, soap powders, stock food, plastics, grains etc

Advantages over conventioanl conveyors

· Easily integrated into existing material transfer systems

· The vertical Olds Elevator has a relatively small footprint

· Operates on any inclination

· Minimal dust generated

· Typically the discharge end has no bearings, seals or a drive, so discharge can be close to the ultimate headroom Discharge rate control

· Gentle handling

· The material in-feed is at the lowest point of the elevator, and can be at virtually floor level

· Minimizing contamination of product and Low maintenance

· The main drive system can be located at any position on the housing to suit easy mounting, wiring and access

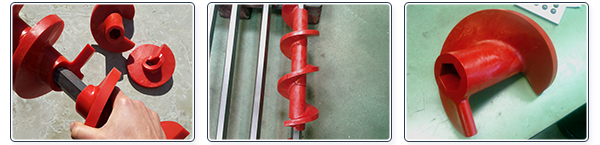

ARCHIMEDYS SCREWS

Archimedys is a new solution for the realization of the Archimedean screws used for the construction of conveyors, feeders, metering units or for bulk treatment installations.

This is simply done by assembling standard screw modules on an axle. When you have locked the assembly with a screw or a nut, your auger is ready for use. You need for example only 20 minutes to build a 7m long screw.

The Archimedys product range is conceived for manufacturers and users of screw conveyors. It has been created for light and medium duty.

Advantages of Archimedys screws

· Easily build your screw without spotting or continuously welding metal flights to a shaft.

· No more intermediate bearings needed on long screw in many applications.

· Strengthened abrasion resistance – up to three times more wear resistant than steel in certain applications.

· Surprising noise attenuation while working.

· Energy savings by reducing the motorization strain and torque.

· Flightings are naturally resistant to corrosion impervious to a wide range of acids, caustics and other chemicals.

· Ecological design allowing the suppression of welding, sandblasting or polyurethane coating in order to protect from corrosion by toxic metals.

Visit manufacturer’s website!.